Below you will find a selection of common water treatment definitions and terms.

- Water Treatment Definitions

- Alternate Terms

- Definition and or Uses

- Activated Carbon

- Activated Carbon Charcoal, Activated Charcoal, Activated Coal, Carbon, Charcoal, Granular Activated Carbon, GAC

- The term activated carbon refers to a material that is used frequently in a range of differing water treatment techniques, such as dechlorination and organics removal. Base products that are utilized to create activated carbon include, but are not limited to: coconut, lignite, and bituminous coal.

- Alkalinity

- Alkaline Water, Dealkalizer, M-Alkalinity, P-Alkalinity

- Alkalinity is the calculated amount of water’s ability to neutralize an acid; it is also known as the measured amount of acid that can be mixed with a liquid without a drastic pH level change occurring. To clarify, alkalinity and pH are not the same. Water doesn’t need to have a high pH to achieve high alkalinity. In the industry, alkalinity is measured as milligrams per liter (mg/L) of equivalent calcium carbonate.

- Anion Resin

- Organic Scavenger Resin, Strong Base Anion, SBA, Tannin Resin, Type 1 Anion, Type ll Anion, Weak Base Anion, WBA

- Anion resin, also referred to as anion exchange resin, is a mixture of small white or yellow beads created from polystyrene material. An anion is a negatively charged ion that contains more electrons than protons. In the process of anion exchange, negatively charged ions in the water are replaced with anions from the resin within the ion exchanger.

- Bed

- Filter Bed, Resin Bed, Softener Bed

- A resin bed refers to the capacity measurement of media or ion exchange resin that water flows through during the water treatment process.

- Brine

- Salt Solution, Saturated Brine

- Brine is a thick concentrate mixture of common sodium chloride, salts, and water. A brine solution of potassium or sodium chloride is used during the regeneration of anion and cation exchange equipment. The brine inside of an ion exchange softening tank is around 26% NaCl by weight, at 60° F.

- Brine Tank

- Brine Holding Tank, Brine Keeper, Brine Maker, Brine Measuring Tank, Salt Bale, Salt Tank

- A brine tank is the vessel used to contain the brine solution that is used in the regeneration of resin beds in water treatment equipment.

- Calcium

- Scale

- Calcium is one of the main elements within the earth’s crust. Dissolved calcium compounds are the reason for hard water. Calcium within water is a major factor in the buildup of scale and soap scum, both of which are clear signs of hard water.

- Catalyst

- Catalytic

- A catalyst is a material that changes the speed or yield of a chemical reaction, without being consumed or altered by the process

- Catalyst Media

- Catalyst Medium

- The term Catalyst media refers to filter media that cause reactions to occur during water treatment. Such materials include: activated carbon, dissimilar metal alloys, manganese greensand, and manganese oxides.

- Cation Resin

- Strong Acid Cation, SAC, Softener Beads, Softener Resin, Weak Acid Cation, WAC, Zeolite

- Cation resin, also known as cation exchange resin, is a mixture of small white or yellow polystyrene beads. A cation is a positively charged ion that has more protons than electrons. In the cation exchange process, the positively charged ions in the water are exchanged for cations from the resin within the ion exchanger.

- Decationize

- Decationized Water

- Decationizing is the process of exchanging cations for hydrogen ions through the utilization of a strong acid in a cation exchanger operating in hydrogen form.

- Degasifier

- Air Stripper, Decarbonator, Degasify, Degasifier, Degassing, Forced Draft Degasifier, VOC Tower

- A degasifier is used in order to remove dissolved gasses from water supplies. Examples of such gases include: carbon dioxide, methane, oxygen and hydrogen sulfide. The removal of these gases is achieved either by air stripping or vacuum degassing. In air stripping, large amounts of air are passed through the water at atmospheric pressure. In vacuum degassing, the water is subjected to pressure below atmospheric pressure.

- Deionizer

- Demineralizer, Demin, DI

- A deionizer removes all ionized materials, both organic and inorganic, through the use of a two-phase ion exchange process. The first step in this process is the removal of positively charged ions through the use of a cation exchange resin, which are replaced with hydrogen ions. The second step is the removal of negatively charged ions by an anion exchange resin, which are then replaced with hydroxide ions. The hydrogen and hydroxide ions then bond to form water molecules. This process is also referred to as demineralization by ion exchange.

- Desilicizer

- A Desilicizer removes silica present in water through an ion exchange process. Typically, a strong base anion exchanger operating in OH- form is used.

- DI Exchange Tanks

- DI Bottles, SDI, Service DI, PE, Portable Exchange, PEDI, Exchange Bottles

- The term DI Exchange tanks refers to tanks that are rented or leased to a facility which lacks the means to regenerate the ion exchange resin on its own.

- Effective Size

- Mesh Size, Average Size

- Effective size is the measured diameter of particles within a medium or resin bed. The effective size for mesh is one that allows 10% of the particles to pass through while retaining the other 90%. Essentially, 10% of the particles or grains should have a smaller diameter than the 90% that remains.

- Feedwater

- Boiler Feed water, Makeup Water, Boiler Make up water

- Feedwater is water that is intended to be fed into a water treatment system for treatment.

- Flowrate

- GPM, Gallons Per Minute, M3/Hr, Feet per Second

- Flowrate is the amount of water or regenerant that passes a specific point within a set amount of time. This measurement is generally given in gpm per square foot or bed area (or L/min). In ion exchangers, flow rate is measured in gpm per cubic feet of resin. Flow rate is a critical factor in designing effective water treatment equipment.

- Groundwater

- Well water

- Groundwater is water that is located beneath the surface of the ground. It is water that seeped into the ground through interstitial spaces in the soil and geological formations.

- Hard Water

- Water Hardness

- Hard water is water that contains dissolved compounds of calcium, magnesium and other trivalent or divalent metallic compounds. The term evolved from water that was described as “hard” to wash in and wasted soap. Dissolved compounds in hard water cause soap to stop lathering, creating an insoluble curdy precipitate. Hard water is also frequently responsible for the buildup of scale on dishes and water boilers, due to excessive buildup of dissolved magnesium and calcium. Water hardness is typically measured in parts per million (ppm) or grains per gallon of calcium carbonate equivalent in the water.

- Hydrogen Sulfide

- Sulfur, Rotten Egg Smell, Sulphur

- Hydrogen Sulfide iis a corrosive, flammable gas that is frequently found within well water. The dissolved gas is typically accompanied by iron and low pH levels. When water contains concentrations of less than one milligram per liter (mg/L) of hydrogen sulfide, it will have a musty or swampy color. At concentrations higher than one mg/L, water takes on a “rotten egg” smell and becomes corrosive to plumbing.

- Makeup Water

- Boiler Makeup Water

- Makeup water is the name for treated water added to a boiler circuit or cooling tower in order to replace water that is lost through evaporation and/or steam leaks.

- Mixed Bed

- Mixed Bed Resin, Mix Bed,

- A mixed bed is a container that holds a mixture of two or more exchange products or filter mediums during a service run.

- Re-bed

- A re-bed is the process of completely removing and replacing the media or resin within a tank. This process is different than a “topping off”, which is the process in which additional resin is added to the tank to replace what has been lost.

- Regeneration

- Regeneration is the process of using a chemical solution, known as a regenerant, to replace the unwanted ions that have been added onto an ion exchange resin during water treatment. The unwanted ions are flushed and replaced with new ions in order to refresh the capacity of the exchange medium for reuse.

- Resin

- Resin used in the process of water treatment refers to ion exchange products made up of specially manufactured organic-polymer beads. A resin bed is utilized in water softening and ion exchange processes in order to eradicate dissolved solids in water.

- Tank

- A tank is the container used in water treatment that houses the ion exchange resins or filter media.

- Tannin

- Tannins are natural, organic, water soluble phenolic compounds that form from the decomposition of vegetation. Tannins are found most often in water where large quantities of decayed vegetation are present, causing a light brown or yellowish coloration of the water. If tannin molecules are present in water that has a pH greater than 6, they form anions and should be treated with anion exchange resins. However, if the pH is less than 5, the tannin-filled water should be treated using activated carbon.

- UV Light

- Ultraviolet light, or UV light, is light that is invisible and has a wavelength between x-rays (100 angstroms) and visible light (3900 angstroms). Ultraviolet light can be used in water treatment systems as a disinfectant.

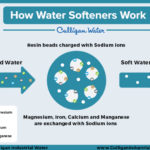

- Water Softener

- A water softener is a vital piece of water treatment equipment that facilitates the reduction and removal of calcium and magnesium ions in order to treat hard water. In municipal and industrial water treatment, the process of water softening is often used to treat lime and lime-soda buildups.

Learn More > Industrial Water Treatment Learning Center